The old saying, “There is a perfect tool for every job,” is particularly true when discussing the efficiency of tube fabricating plants. How you manage your workers’ time and effort can often determine whether you are making money or losing it. Therefore, having the right equipment is not just a matter of making work easier for everyone; it may also …

How To Fix Tube Cutting Bottlenecks

The term “bottleneck” refers to a slowdown or stoppage in any production process. In tube cutting, bottlenecks typically occur at certain points on the production line. In order to fix these problems, it is important for planners to understand how their process becomes bottlenecked in the first place and what steps will solve the situation. Finding and Fixing Production Bottlenecks …

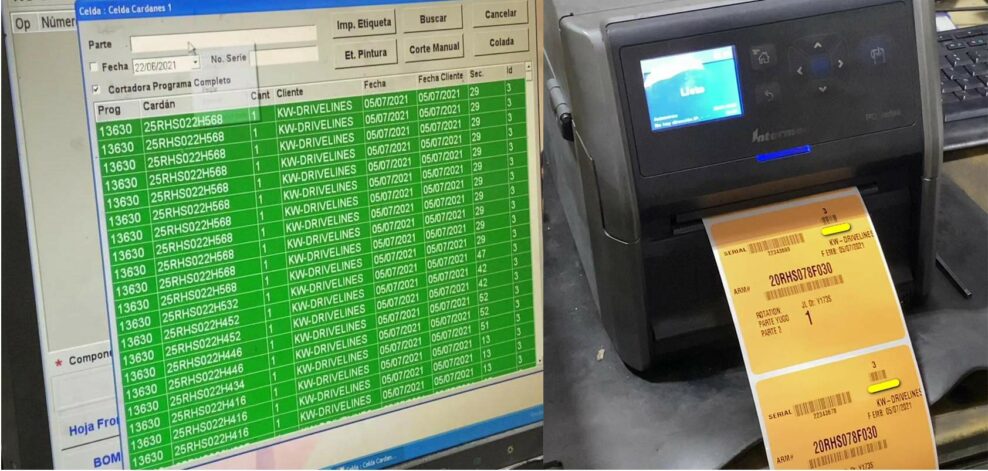

Tube Cutting and MES Integration to Improve Efficiency

Efficient production is the key to profitability for any manufacturing company. As manufacturing plants work to improve efficiency, many are utilizing a Manufacturing Execution System (MES), which is a computerized solution on the manufacturing floor to process raw material into finished goods. An MES monitors and controls the complex data surrounding these processes with the goal of ensuring efficient output. …

Getting Creative With Rotating Head Cutoff Machines

Rotating head tube cutoff machines have completely reorganized the workflow of producing and processing in the metal pipe industry. Those with factories or plants dedicated to creating metal pipe products are discovering that with a rotating head cutoff machine, they can quickly streamline their procedures and make the entire process less labor-intensive and more efficient. However, many of these same …

The Workflow of Metal Tube Processing

For a manufacturer and processor of all types of metal tube products, such as pipes, it is very important to have good productivity and workflow on the factory floor. In fact, it is not an exaggeration to say that workflow can make the difference between a profitable business and one that does not make money for the owner. Focusing on …

Rotating-Head Tube Cutoff Safer Than Conventional Lathe

One of the biggest concerns of any business, and particularly those that handle heavy or sharp materials, is safety. Finger and hand injuries can be life-changing for employees, and can result in lost productivity and may end up increasing insurance costs. Even a minor injury can cause serious issues. Not only do you want to keep your workers safe because …

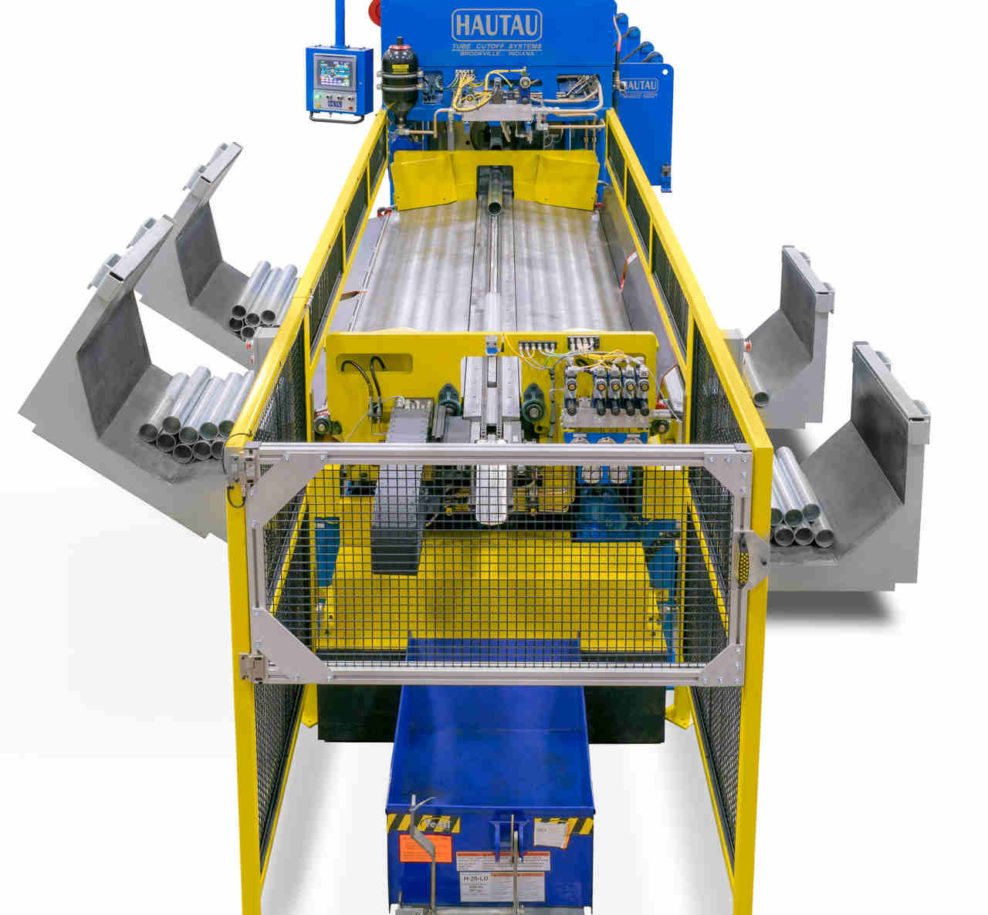

The Advantages of Loading/Unloading Systems with Tube Cutoff Machines

A typical tube cutoff machine is built on a relatively simple and straightforward concept. The machine is loaded by a worker with a number of metal tubes, the cutting mechanism cuts them to length, and the tubes are unloaded by a worker. This setup is fine for small batches and for a company with plenty of low-cost labor, but what …

Automatic Tube Loading Options

Tube fabricators and processors are always looking for ways to increase production and reduce costs. With any high-volume tube fabricating operation, the first steps in the process are handling tube bundles, cutting tubes to length and then moving the cutoff tubes to the next operation. This tube cutting process is required for all your raw tube material, and it can …

- Page 2 of 2

- 1

- 2