Efficient production is the key to profitability for any manufacturing company. As manufacturing plants work to improve efficiency, many are utilizing a Manufacturing Execution System (MES), which is a computerized solution on the manufacturing floor to process raw material into finished goods. An MES monitors and controls the complex data surrounding these processes with the goal of ensuring efficient output.

How Does An MES Work?

An MES works by gathering and tracking real-time input on a given production cycle. The MES generally begins with the instruction given for the product, in the form of an order or other input, and goes through the delivery stage, giving the manufacturer a true “birds-eye view” of the entire process. The MES may collect data about material management and plant activities, as well; this information helps managers and owners make informed decisions about floor operations.

How Can Integrating MES Help With Metal Tube Production?

In most cases, metal tube production begins with cutting raw material to size. Therefore, the logical starting point for integrating MES is with the tube cutoff operation. If this critical component is considered in the MES structure, metal tube production efficiency can feasibly skyrocket.

However, older tube cutting machines, particularly those based on an outdated worker-driven lathe or sawing system, may not be capable of integration with an MES system, which is computer based. If a production floor is still operating with workers reading tube sizes and lengths from printed work-orders, efficiency will necessarily slow down. However, there is good news for producers who are still working with older systems; integrating an MES may be as simple as adding a rotating-head cutoff machine to their current production line.

Integrating MES is Simple with Rotating Head Cutoff Machines

Because modern tube cutoff machine software is capable of receiving work orders directly from the MES, adding a rotating head cutoff machine to a production lineup instantly increases efficiency and cuts costs.

If the raw material is a metal tube or pipe, the MES work order might include tube diameter, wall thickness, and cut length, plus a code for tracking the product flow through subsequent operations. The machine operator would load the proper size tube into the cutoff machine, execute the program through the software, and then allow the MES software to control the servo-driven cutting head of the tube cutoff machine and produce the required lengths. Instantly, the worker’s role in the process is optimized and the processing of the final product is accelerated. And because the tube cutting data is “pushed” directly into the controller, simple operator entry mistakes are eliminated,

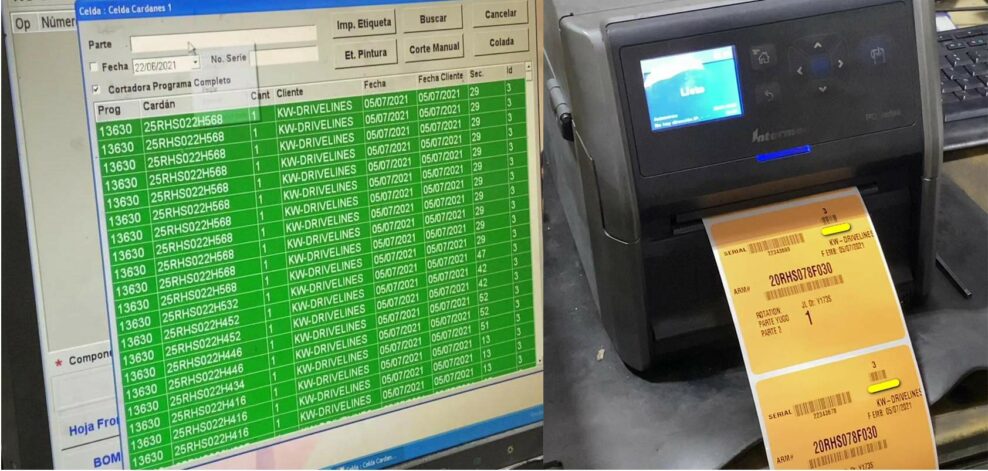

Further, a computerized tube cutoff machine can instantly transfer all the MES data to downstream secondary operations, such as printing serial numbers, material codes and heat numbers. Because this process is automated with the use of an MES, at least one step in the production run is eliminated completely, freeing workers to spend more time handling the initial setup of the run. The software sends a confirmation message to the MES when a part has been cut, and the parts can be pin-stamped or laser etched with bar codes and tracking numbers.

Workers are not the only group to experience an increase in efficiency through the use of MES. Supervisory software can also be integrated that monitors production from cutoff through final assembly. This helps managers identify and correct any delays or shortages before overall production is affected.

If you are considering adding a rotating-head cutoff machine to your production floor, give the professionals at Hautau a call. Hautau control engineers will work with the customer to develop and fine-tune the data transfer software, as well as provide real-time support throughout the implementation of the system and ongoing VPN support to adapt to customer changes in their MES structure. Let us know today how we can help!