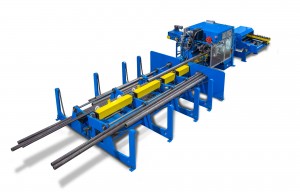

RC50 5" Cutoff Lathe

High-Speed Automatic Cutoff Lathe

The RC50 Cutoff Lathe has an intermediate capacity to cutoff a wide range of popular tube and pipe. If you are using a bandsaw or cold saw, you know that the sharp edges have to be deburred or chamfered to produce high-quality workpieces. And if you're using a conventional cutoff lathe, you can't chamfer all the tube edges. Our cutoff lathes combine cut-off and chamfering in one operation. These versatile machines can cut, face, chamfer, groove and bore quickly and efficiently. This eliminates secondary operations and reduces labor.

Tube OD range: 1.0 inch to 5 inch

Wall Thickness: .032 inch to 1 inch

Cut Lengths: 1.0 inch min / 480 inches max

• Multiple cut lengths per tube

• Random lengths are automatically measured and optimized

Our 30HP cutoff lathe headstock has ample power for fast cutting, and includes constant surface speed (CSS) control to maintain optimum production rates. The dual hydraulic chucks hold the tube on both sides of the cut and adjust automatically for quick diameter changes. Full servo control of the tools and tube position let's you produce complex grooving and weld-preps in a single chucking with no secondary operations needed.

RC50 Tube Cutoff Lathe Advantages:

- Our rotating-head machine design allows complex tube machining operations

- Chamfer OD and ID on both tube ends

- Cut long lengths without “steady rests”

- Cutoff piece is held and does not “break loose”

- Chucks automatically adjust for tube or pipe size

- No collet or jaw changes

- Fast, pushbutton changeover for tube diameter and cut-off length

Many conventional tube cutting systems leave sharp tube ends. Hautau cutoff lathes hold the tube stationary during the cut while the rotating head cutoff moves the tools in for cutting and chamfering. The tube is gripped by two tube chucks that position the tube for cutting the inside and outside chamfers. The tube lengths are precise and chamfer depths are programmable.