RC30 3" Automatic Pipe Cutoff Lathe

RC30 Automatic Pipe Cutoff Lathe

The Hautau RC30 Automatic Pipe Cutoff Lathe is the smallest of our rotary-head cutoff lathes to include full-range chucking, for high-speed cutting and chamfering of pipe or tubing up to 3 inches in diameter. If you are using a bandsaw or cold saw to cut tube or pipe, you know that the sharp edges have to be deburred, beveled or chamfered to produce high-quality workpieces. Our pipe cutoff machines combine cut-off and complete endfinishing in one operation, and with our built-in software routines you can cut grooves, bores and weld-prep bevels.

To ensure you get continuous production from your cutoff system, we build a full line of automatic tube loaders that handle full tube bundles safely and deliver single tubes into the cutoff machine. Our tube loaders all have automatic changeover for diameter, and they measure the length of each incoming tube for material optimization.

The high-speed tube feeding system features hydraulic servo control for precise cut lengths. And our built-in length nesting software helps you get the get the best material utilization from each mill length.

Tube OD: 0.50 inch to 3.0 inch

Wall Thickness: .02 inch to 1.0 inch

Cut Lengths: 0.75 inch min / 480 inches max • Multiple cut lengths per tube • Random length tubes are automatically measured and optimized

Pipe cutting and double-end chamfering is performed in a continuous process, in one chucking. No secondary operations.

- The Hautau RC30 has the fastest tube feed system we offer, with advance rates of 50 inches per second.

- The 30HP headstock has constant surface speed (CSS) control to maintain optimum production rates.

- Our intuitive software includes built-in programs for grooving, turning, boring and special chamfers.

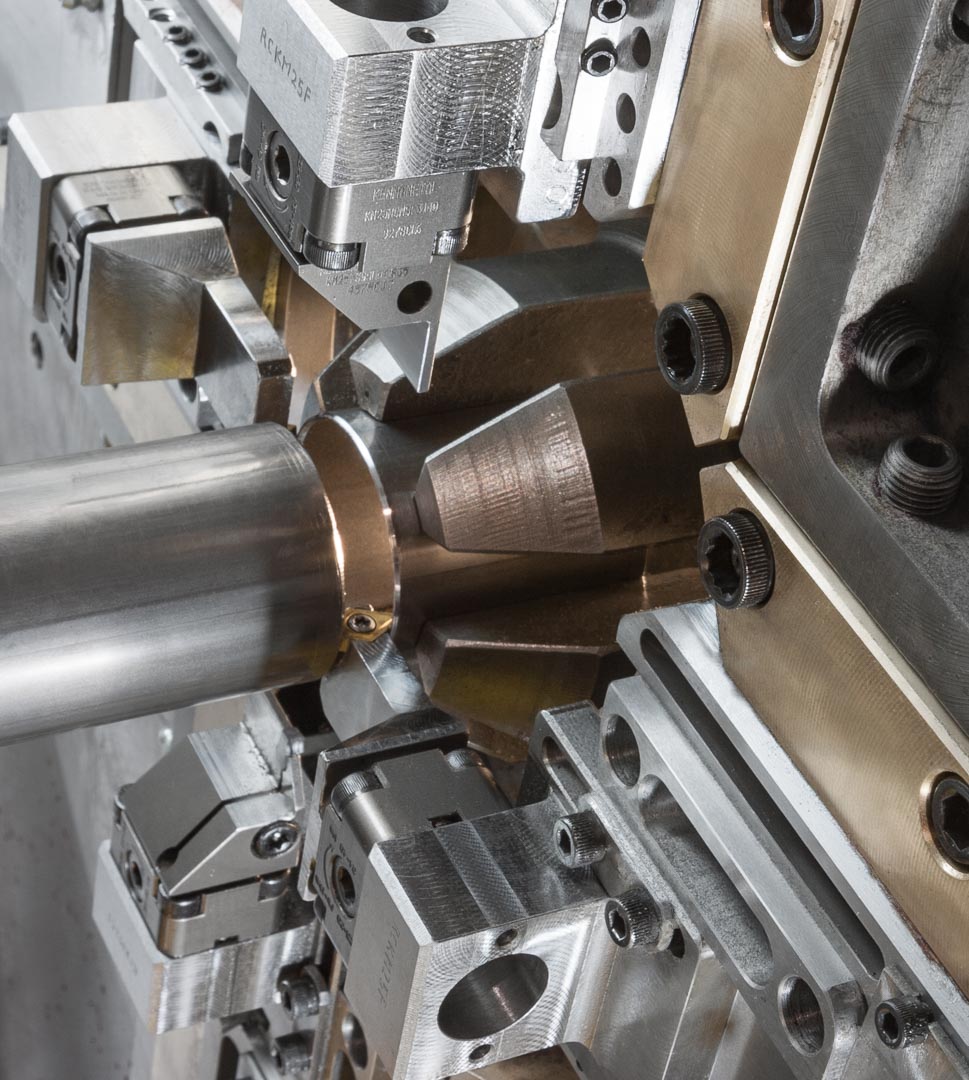

- Quick-change tooling cartridges for cutting and chamfering tubes a small as .62″ diameter.

- The tube chucks adjust automatically to the programmed diameter, so there's no collet or jaw replacement.

- Cut up to 10 different lengths per tube for the best material utilization even from random length bundles.

RC30 Pipe Cutting and Chamfering Machine

When compared to conventional tube saws and lathes, Hautau rotating-head tube and pipe cutoff lathes represent a major advance in tube cutting technology. The tube is held stationary by two chucks while the cutting headstock rotates around the tube. After cutting, the chucks move and position the tube ends for secondary machining operations such as beveling, grooving, boring and OD turning.

When combined with our tube loading and tube unloading options you get a high-production "tube vending machine" with quick changeovers and low labor input.

- You can cut pipe and tube to lengths that are accurate within .005″.

- You can chamfer the inside and outside of both tube ends.

- Our built-in programs allow you to cut or roll grooves anywhere along the tube length.

- We stock special tooling for boring and grooving the tube.

- The touchscreen has simple screens for fast changeover for tube diameter and cut-off lengths.