A rotating head tube cutoff system offers numerous advantages over traditional lathes, particularly in terms of worker safety, efficiency, precision, and ergonomics. This advanced technology significantly improves the working conditions and productivity of operators in the metalworking industry. For manufacturers who are worried about protecting their workers, a rotating head cutoff system may be the solution that not only provides …

How Integrated Machine Safety Improves Manufacturing Output

One of the most important concerns facing any company today is worker safety. Maintaining a safe environment is among the top priorities for most organizations, since safety translates into higher production levels, lower insurance rates, and better overall worker performance. With fewer lost-time accidents, companies run more smoothly and save money, as well as provide a better place for their …

Tube Beveling and Chamfering Options

Processing metal tubes starts with two major groups of operations: cutting and end-finshing. Many machines can do one of these things well, but not the other. For example, some stationary lathe machines cut metal tubing with a fair degree of accuracy, although vibration tends to be a problem for conventional cut-off lathes, leading to inaccurate cuts and high tool wear. …

Finishing Processes for Metal Tubes

If you use tubing in manufacturing your product, an out-of-date tube cutting process may be limiting your overall production. You might consider just upgrading to an automatic cutoff saw or an automatic cutoff lathe. However, if your specifications require that the cut pieces to be deburred, chamfered or end-finished, the cutting operation is the easy part. The secondary deburring or …

Preventative Maintenance Can Help Extend Machine Life

Having made the wise investment in a rotating-head tube cutoff machine, the next step should be obvious: taking care of your machine so you get continuous production for years to come. Unfortunately, this may not be as easy as it sounds. Many business owners do not understand the maintenance schedule for a high-end machine very well, or the managers they …

Creating a Seamless Workflow with MES Software

When we think about making money with any business, we must necessarily consider how a company conducts its everyday activities. Workflow is a concept that has a huge impact on not only productivity, but also on profitability for any business. Simply put, the better a company’s workflow, the more likely it is to generate profits. Unfortunately, many businesses lose potential …

Eliminating Steps in Production With A Rotating-Head Cutoff Machine

One of the biggest problems producers face in processing metal tubes, particularly if they want to finish as well as cut, is excessive steps. Every time production stops for changeovers or recalculations, time is wasted unnecessarily. The ideal system is streamlined, offering producers seamless loading, cutting, finishing, and unloading or packaging options. But for many producers, this process is cumbersome. …

Five Ways to Streamline Your Production Process

When it comes to your production processes, streamlining is the key to increasing profitability. Although everyone realizes this, not all business owners are sure how to go about making their processes more efficient and effective, reducing waste, or spotting areas needing improvement. Here are a few tips to help you streamline production and increase worker safety and productivity. Improve quality …

Cutting Tubes In-House or Buying Pre-Cuts

Manufacturers who use metal tubing in their products have a few choices when it comes to buying their raw tube material. High-volume operations usually purchase tubing directly from a mill and use high-speed, automatic tube cutting machines. These cutting systems often transfer the cut pieces directly to a complete production line. Low-volume manufacturers generally purchase full-length tubing and use a …

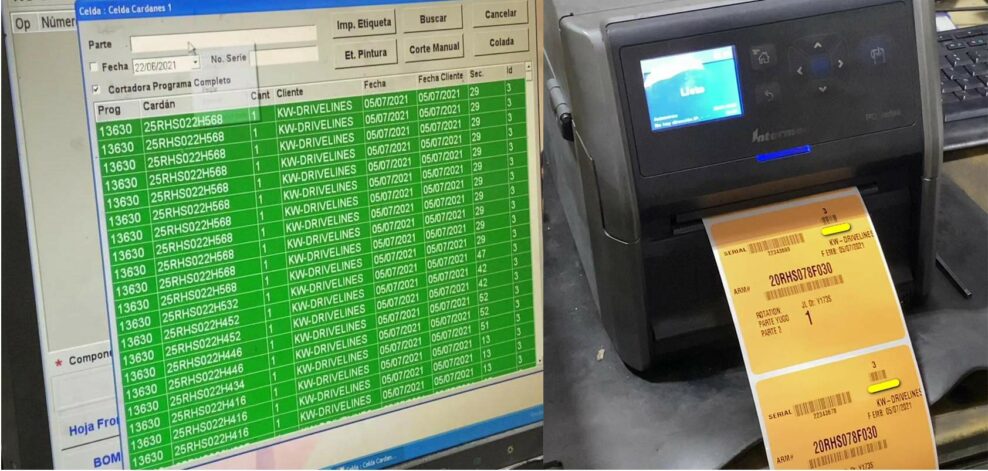

Tube Cutting and MES Integration to Improve Efficiency

Efficient production is the key to profitability for any manufacturing company. As manufacturing plants work to improve efficiency, many are utilizing a Manufacturing Execution System (MES), which is a computerized solution on the manufacturing floor to process raw material into finished goods. An MES monitors and controls the complex data surrounding these processes with the goal of ensuring efficient output. …

- Page 1 of 2

- 1

- 2