A typical tube cutoff machine is built on a relatively simple and straightforward concept. The machine is loaded by a worker with a number of metal tubes, the cutting mechanism cuts them to length, and the tubes are unloaded by a worker. This setup is fine for small batches and for a company with plenty of low-cost labor, but what happens when a company has high-volume runs where the labor costs must be minimized. You’re struggling to find enough workers, and the orders are piling up due to the length of time it takes to load, unload and restack metal tubes?

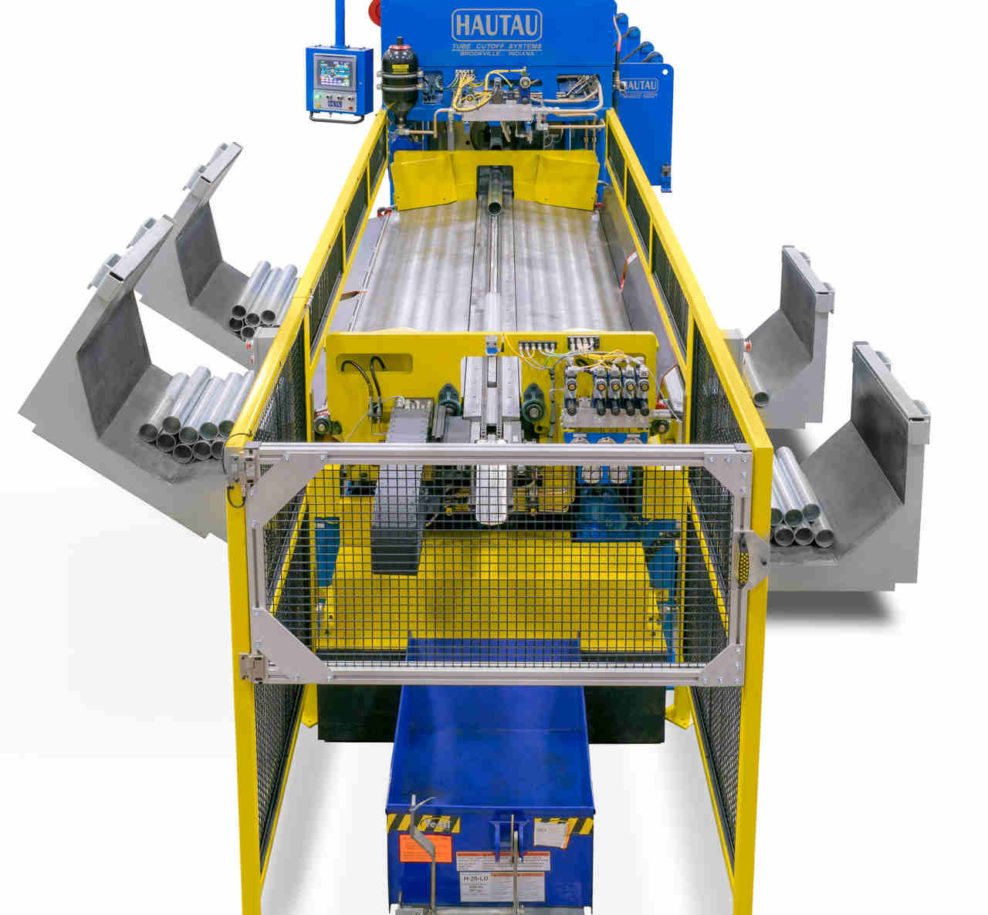

Fortunately, Hautau has come up with ways to streamline this process. Best of all, these features can be added to your tube cutoff machine easily and work seamlessly as part of a larger design. With the right accessories, you can create a system that is hands-off from start to finish, minimizing the amount of labor required for large production runs.

The Basics of Handling Large Batches

When you have a large batch of tubes to run, there are several factors that must be considered:

- Number of tubes. Many cutoff machines aren’t designed to handle large batches, requiring the runs to be broken into segments. With a tube-loading system, larger groups of tubes, in some cases up to 10,000 pounds per bundle, can be handled at once.

- Number of different cuts. With a traditional cutting machine, a single cut length is produced, but with a servo-driven tube-feeding system you can program several different cut lengths from each tube. This reduces wasted material and scrap.

- Loading mechanism. Some machines or loaders are not designed for safe loading from a crane or forklift. When that is the case, workers must manhandle the small groups of tubes into the machine. Ideally, the loading system can handle full tube bundles and run un-attended for long periods.

- Tube Offloading. Just as tube loading is a consideration, offloading is a concern as well. Once the tubes are cut, most cutoff machines require workers to sort and stack them. With an automated tube handling system, your tubes can be automatically sorted into groups or stacked in containers. If there are secondary operations required, the tubes can be transported efficiently and with minimal labor. In some instances, a customized robot solution may be the best fit.

- Operator Safety. As-cut tubes from most machines have burrs and rough edges that can result in hand injuries to workers. A machine that uses a rotary-head cutting mechanism, however, can chamfer and deburr the tubes in one operation. This increases safety while also preparing the tubes for assembly or further processing.

Hautau has been creating solutions for all of these issues for years. Our tube-loading systems include bundle loaders, long-length transfer systems and shaped-tube loaders. And our customized tube off-loading systems reduce labor while ensuring you get consistent production.

If you are interested in learning more about our tube loading options or in having a custom loading option designed for your company, give us a call today!