Products

Hautau RC cutoff machines incorporate a rotating-head with up to four tool slides that allows cutoff plus chamfering, radiusing, grooving and turning. Because both ends of the tube are held rigidly after cutoff, inside chamfering is possible on both ends of the tube. By holding the tube stationary during cutting, these machines eliminate problems associated with spinning tubes such as noise vibration and surface marking. The tube is chucked and advanced more precisely, and can be moved under servo control during endfinishing operations. The full-range chucks eliminate having to remove and replace collets or pads when changing diameters.

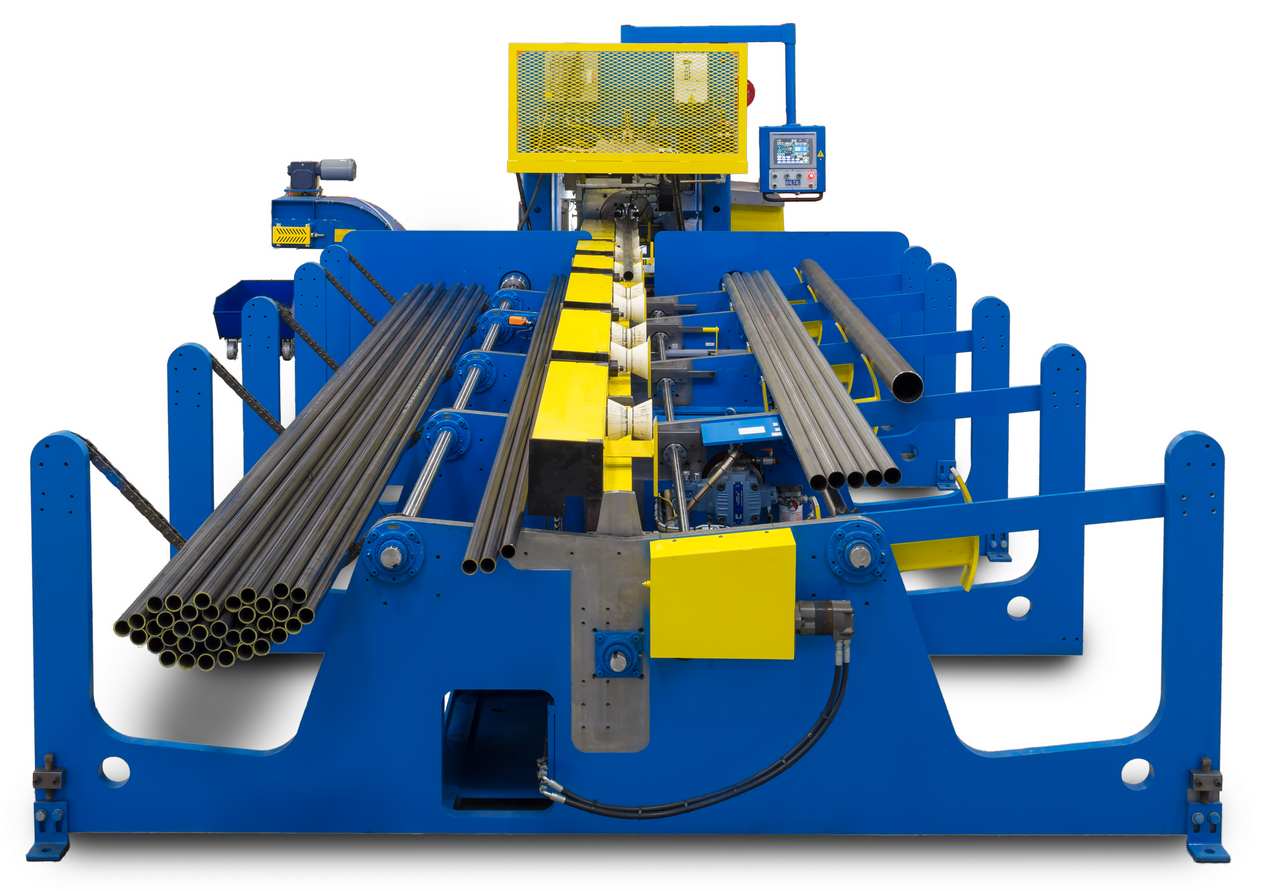

tube loading & unloading automation