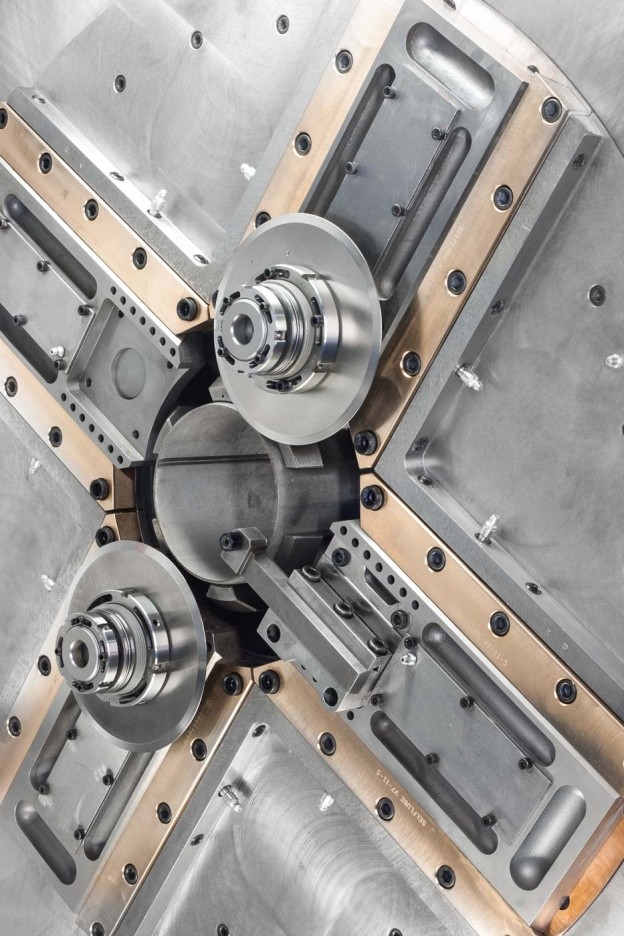

RC60 Rotary-Head Tube Cutoff Machine 7"

Advanced Rotating-head cutoff machine that cuts tube and chamfers in one operation.

The RC60 Rotating-Head Cutoff Machine is our most popular model, with a diameter range of 1.5" to 7" and capacity to cutoff a wide range of popular tube and pipe. If you are using a bandsaw or cold saw to cut tube or pipe, you know that the sharp edges have to be deburred or chamfered to produce high-quality workpieces. And if you're using a conventional cutoff lathe, you can't chamfer all the tube edges. Our rotary-headstock cutoff machines combine cut-off and chamfering in one operation. These versatile machines can cut, face, chamfer, groove and bore quickly and efficiently. This eliminates secondary operations and reduces labor.

OD: 1.5 inch to 6.75 inch

Wall Thickness: .040 inch to 1.0 inch

Cut Lengths: 0.75 inch min / 480 inches max • Up to three cut lengths per tube • Random lengths are automatically measured and optimized

- 30HP rotary head stock has ample power for fast cut off

- Constant surface speed (CSS) ensures optimum production rates

- Tube chucks adjust automatically to the programmed diameter

– no downtime for collet or jaw replacement. - Cut, face, chamfer and groove tubes in one chucking

- Eliminate secondary operations and reduce labor

- Cut mixed long and short lengths for the best material utilization even when cutting from random length bundles.

- Tube runout and sorting systems available for multi-length cutting.

What's different about our rotating-head tube cutoff machines?

- Our machines benefit from over 45 years of continuous development.

- The cutoff headstock rotates around the tube.

- The dual hydraulic chucks hold the tube on both sides of the cut.

- There are no collet or chuck jaw changes required.

- The tube chucks will automatically adjust for tube or pipe size.

- Pushbutton changeover is fast for diameter and cut-off length.

- The cutoff piece is held and does not break loose.

- You can cut long lengths without “steady rests”.