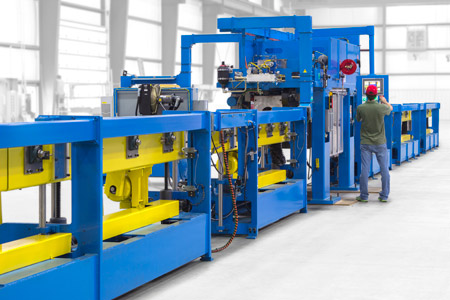

Custom Systems

Custom Solutions for your special application

One of the keys to achieving a cost-effective tube and pipe cutting process is to reduce handling steps and minimize the labor required.

Our experience in tube cutting and endfinishing, plus our knowledge of associated processes such as drawing, pilgering, extruding, swaging and bending allows us to provide the exact system you need for your application.

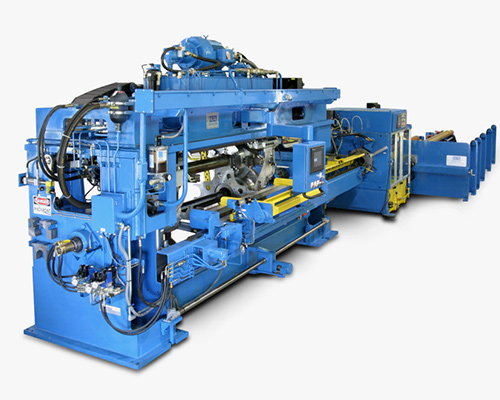

If your process requires tube-end boring or deep beveling operations, we can design and build high-performance systems that combine our RC Rotating-Head Tube and Pipe Cutoff Machines with our Tube Endfinishers.

For Sections Up To 8 Feet

If you need precision boring, facing or beveling of tube lengths up to 8’, we can link directly from cut-off to our massive CC60 double-end finishing machine.

A runout conveyor carries cut tubes to the CC60, where the index dial transfer the tubes through length-check, boring and blow-off stations.

We can also incorporate drilling, spot facing and ID grooving operations. One operator oversees the whole cutting/boring system.

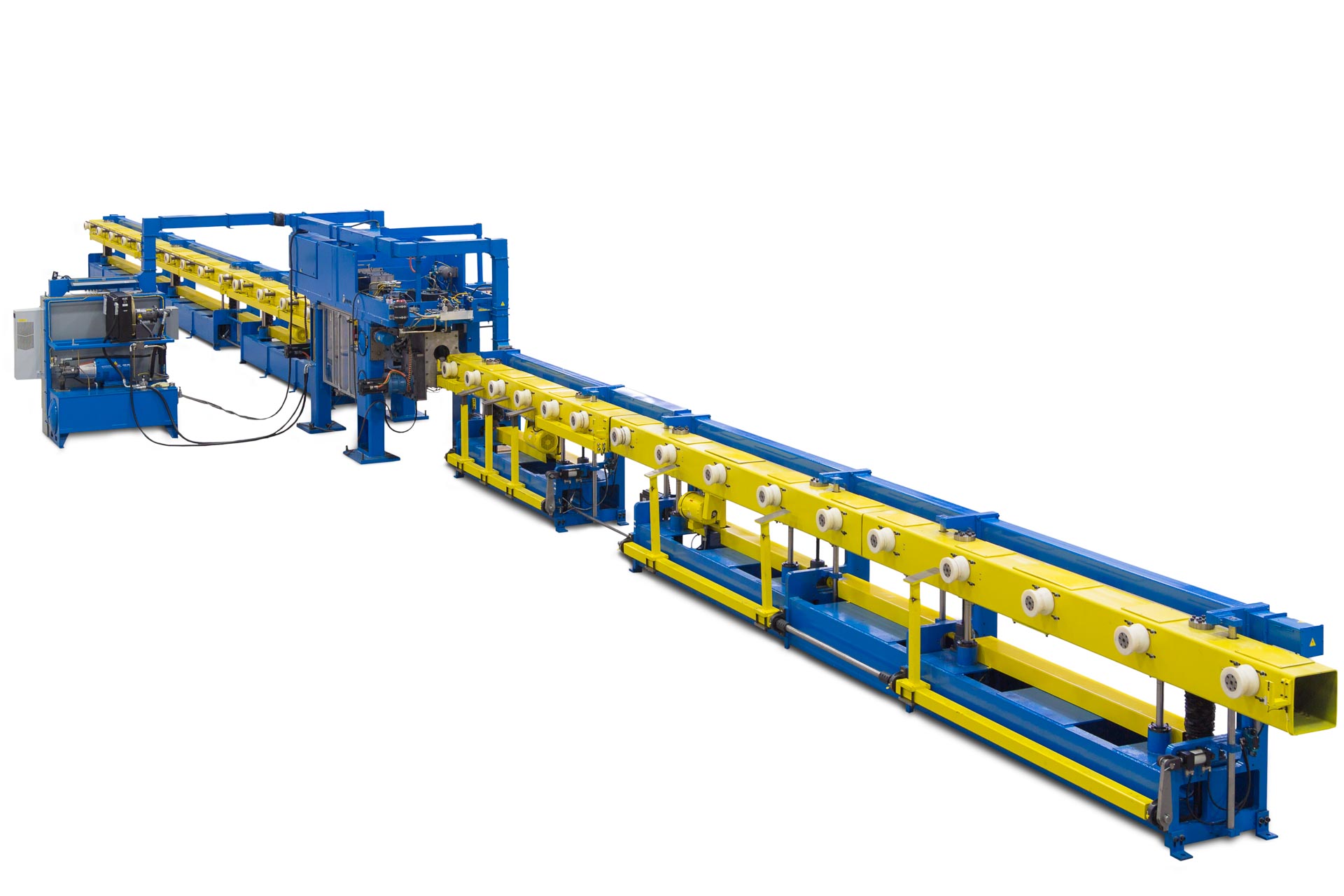

For Mill Length Tubes …

For mill-length tubes, we can supply a powered V-roll system to carry tubes out of the cutoff machine.

Tubes are then transferred via walking beam through two C-Series single-end beveling machines.

Updating Your Existing System

If you need a tube endfinishing system to tie into your existing tube mill or finishing floor, we can supply a walking beam transfer system integrated with two C-Series single-end beveling machines.

We also provide custom retrofit packages to replace out-dated inline cutoff machines with our RC Rotating-Head cutoffs.

The Support You Need

When you buy any system from Hautau, you get innovative design, top-quality construction, installation assistance and guaranteed performance. After the sale, you get high-priority technical support, including remote diagnostics, for as long as you own your machine.